There are four main types of welding: MIG, TIG, arc and Oxyacetylene. Each differs in ease of use, accuracy, cost and finish, so it’s essential to ensure that you are proficient in...

Best Sellers in Workshop Tools and Equipment

Discover a comprehensive range of premium workshop tools and equipment tailored to meet the diverse needs of businesses across various sectors. Our collection includes everything from power tools, hand tools, to safety equipment, all designed to enhance productivity and ensure the smooth running of your operations. We understand that having the right tools at your disposal is crucial for the success of your business, and that's why we offer only the best in terms of quality and performance.

Whether you're in the construction industry, automotive sector, or any other business requiring workshop tools and equipment, our offerings will meet your specific needs. We've carefully selected each item in our range to ensure it offers the durability, reliability, and efficiency that businesses demand. With our tools, you can rest assured that you're investing in equipment that will always stand the test of time and deliver outstanding results.

Explore our extensive selection of workshop tools and equipment today, and experience the difference that high-quality tools can make to your business operations. We're committed to helping businesses like yours achieve their goals by providing top-tier tools and equipment. Don't compromise on quality – choose our workshop tools and equipment for superior performance and longevity.

Choosing the Right Workshop Tools and Equipment

Workshop tools and equipment are available in various types, each designed for a specific purpose. From simple hand tools for basic tasks to more specialised equipment for professional jobs, selecting the right tools for your needs is crucial. Our extensive range includes durable workshop tools and equipment, making it easy for you to find the right products for your needs.

Ensuring Comfort and Efficiency in Your Workshop

Seasonal changes can significantly impact work attitudes and productivity. Our workshop tools and equipment range includes Heaters and Dehumidifiers for the winter months and large Industrial Fans for hot summer days. These can ensure ideal working temperatures for your staff, even in very large workshops. Additionally, our selection of Tool Chests and Toolboxes can help you store your tools and equipment safely and efficiently.

Things to Consider

- Quality and durability: When purchasing workshop tools and equipment, it is essential to consider the quality and durability of the products. Look for reputable brands known for their reliability and long-lasting performance.

- Safety features: Safety should be a top priority when selecting workshop tools and equipment. Ensure that the products have appropriate safety features, such as guards, safety switches, or protective covers, to minimise the risk of accidents or injuries.

- Compatibility: Consider the compatibility of the tools and equipment with your existing workshop setup. Check if they can be easily integrated with your current machinery or if any additional modifications are required.

- Ease of use: Look for tools and equipment that are user-friendly and intuitive to operate. Consider the ease of setup, adjustment, and maintenance to ensure that your team can efficiently work with them without significant training or complications.

- Ergonomics: Consider the ergonomics of the tools and equipment, especially if they will be used for extended periods. Look for features like comfortable handles, adjustable heights, or ergonomic designs that reduce strain and fatigue on the user.

- Efficiency and productivity: Assess the efficiency and productivity benefits that the tools and equipment offer. Look for features like fast operation, high accuracy, or automated functions that can help streamline your workflow and improve overall productivity.

- Versatility: Consider the versatility of the tools and equipment, especially if you have diverse workshop needs. Look for products that can perform multiple functions or offer interchangeable parts to maximise their utility and reduce the need for additional purchases.

- Maintenance and servicing: Evaluate the maintenance requirements and availability of servicing for the tools and equipment. Consider factors such as the ease of cleaning, availability of spare parts, and accessibility to professional technicians for repairs or regular maintenance.

Frequently Asked Questions

What are Workshop tools and equipment?

Workshop tools and equipment refer to the various tools and machinery used in a workshop or a manufacturing facility for carrying out different tasks and operations. These tools and equipment are specifically designed to assist workers in performing their tasks efficiently and safely. Some common workshop tools and equipment include:

1. Hand tools: These are manual tools that are operated by hand, such as hammers, screwdrivers, wrenches, pliers, chisels, files, and saws.

2. Power tools: These are tools that are powered by electricity, compressed air, or other power sources. Examples include drills, grinders, sanders, saws, nail guns, and impact wrenches.

3. Measuring and marking tools: These tools are used to measure and mark materials accurately. Examples include tape measures, rulers, callipers, squares, levels, and marking gauges.

4. Cutting tools: These tools are used for cutting and shaping materials. Examples include cutting pliers, scissors, utility knives, hacksaws, and shears.

5. Welding and soldering equipment: These tools are used for joining and repairing metal parts. Examples include welding machines, soldering irons, torches, and welding helmets.

6. Fastening tools: These tools are used for joining or securing materials together. Examples include screwdrivers, wrenches, drills, nail guns, staplers, and clamps.

7. Material handling equipment: These tools are used for lifting, moving, and transporting heavy materials. Examples include cranes, forklifts, pallet jacks, hoists, and trolleys.

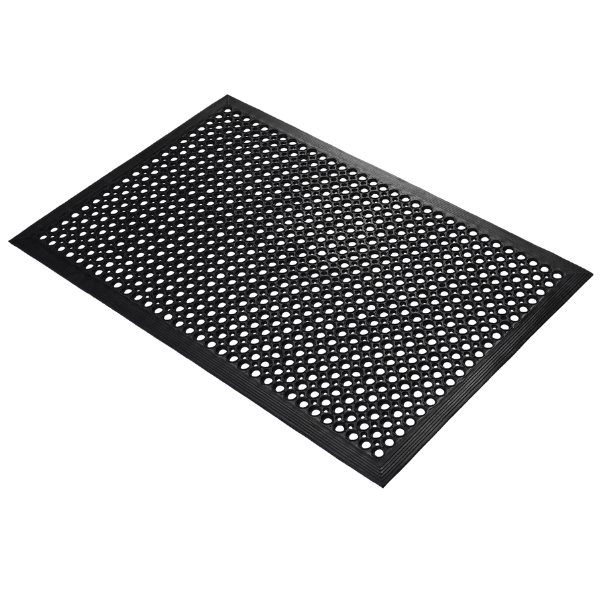

8. Safety equipment: These tools and equipment are used to ensure the safety of workers in the workshop. Examples include safety goggles, gloves, helmets, ear protection, dust masks, and fire extinguishers.

9. Cleaning and maintenance tools: These tools are used for cleaning and maintaining the workshop and its equipment. Examples include brooms, mops, vacuum cleaners, lubricants, and cleaning solvents.

10. Storage and organisation equipment: These tools and equipment are used for storing and organising tools and materials in the workshop. Examples include toolboxes, shelves, cabinets, pegboards, and tool racks.

These are just some of the common workshop tools and equipment. The specific tools and equipment used in a workshop may vary depending on the type of work being carried out and the industry.

How do I choose the right tools for my workshop?

Choosing the right tools for your workshop can be a daunting task, but with careful consideration, you can make informed decisions. Here are some steps to help you choose the right tools:

1. Assess your needs: Determine the type of projects you will be working on in your workshop. Consider the materials you will be working with and the specific tasks you need to accomplish. This will help you identify the essential tools you need.

2. Research: Once you have identified your needs, research the different tools available in the market. Read reviews, compare features, and consider the reputation of the brands. Look for durable, reliable, and suitable tools for your specific requirements.

3. Set a budget: Determine how much you are willing to spend on tools. This will help you narrow down your options and prevent overspending. Remember to consider the long-term value and quality of the tools rather than just the initial cost.

4. Prioritise essential tools: Start by purchasing the essential tools that are necessary for most projects. These may include a workbench, power drill, circular saw, hand tools (screwdrivers, pliers, wrenches), measuring tools (tape measure, level), and safety equipment (goggles, gloves).

5. Consider versatility: Look for tools with multiple functions or interchangeable parts. This will help you save space and money in the long run. For example, a power drill with various attachments can be used for drilling, sanding, and driving screws.

6. Quality and durability: Invest in high-quality tools that are built to last. While they may be more expensive initially, they will save you money in the long term as they will require fewer repairs or replacements. Look for tools made from durable materials and backed by warranties.

7. Ergonomics and comfort: Consider the ergonomics of the tools you are purchasing. Tools that are comfortable to hold and use will reduce fatigue and increase productivity. Look for features like rubberized grips and adjustable handles.

8. Seek expert advice: If you are unsure about certain tools or brands, seek advice from professionals or experienced woodworkers. They can provide valuable insights and recommendations based on their own experiences.

9. Start small and expand gradually: You don't need to buy all the tools at once. Start with the essential ones and gradually expand your collection as you gain more experience and tackle more complex projects.

10. Safety considerations: Always prioritise safety when choosing tools. Look for tools with safety features like blade guards, safety switches, and proper ventilation. Additionally, invest in safety equipment such as goggles, ear protection, and dust masks.

Remember, choosing the right tools for your workshop is a personal decision based on your specific needs and preferences. Take your time, research thoroughly, and make informed choices to build a well-equipped workshop.

What Industries can these tools be used in?

It would be helpful to know which specific tools you are referring to to provide a more accurate answer. However, in general, various tools can be used across multiple industries. Some common examples include:

1. Hand tools (screwdrivers, wrenches, hammers): These are used in construction, automotive, manufacturing, and maintenance industries.

2. Power tools (drills, saws, sanders): These are commonly used in construction, woodworking, metalworking, and manufacturing industries.

3. Diagnostic tools (multimeters, oscilloscopes, thermal cameras): These are used in electrical, electronics, and automotive industries for troubleshooting and maintenance.

4. Cutting tools (knives, blades, scissors): These are used in industries such as food processing, textile, packaging, and manufacturing.

5. Measurement tools (calipers, tape measures, levels): These are used in construction, engineering, manufacturing, and woodworking industries for precise measurements.

6. Welding tools (welding machines, torches, electrodes): These are used in metal fabrication, construction, automotive, and manufacturing industries.

7. Cleaning tools (vacuum cleaners, pressure washers, brooms): These are used in industries such as janitorial services, hospitality, healthcare, and manufacturing.

8. Gardening tools (shovels, rakes, pruners): These are used in landscaping, agriculture, gardening, and horticulture industries.

These are just a few examples, and many more tools can be used in various industries depending on their specific applications.